Beautiful Work Tips About What Size Wire For 60 Amp

What Size Wire For 60 Amps? Electrical Wiring Details

Choosing the Right Wire

1. Understanding the Basics

So, you're tackling an electrical project involving a 60 amp circuit? Awesome! But before you even think about flipping any breakers, let's talk wire. Choosing the right wire gauge isn't just about getting the electricity flowing; it's about safety, preventing fires, and making sure your appliances don't decide to stage a revolt due to insufficient power. Think of it like this: you wouldn't use a garden hose to fill a swimming pool, right? Same concept here.

The key term here is "what size wire for 60 amp." The goal is to ensure that the wire can safely handle the electrical current without overheating or causing a fire hazard. Undersized wire is a huge no-no; imagine trying to squeeze a gallon of water through a straw — not pretty, and potentially destructive. Using the right size minimizes resistance, keeps the wire cool, and ensures a steady flow of electricity to whatever you're powering.

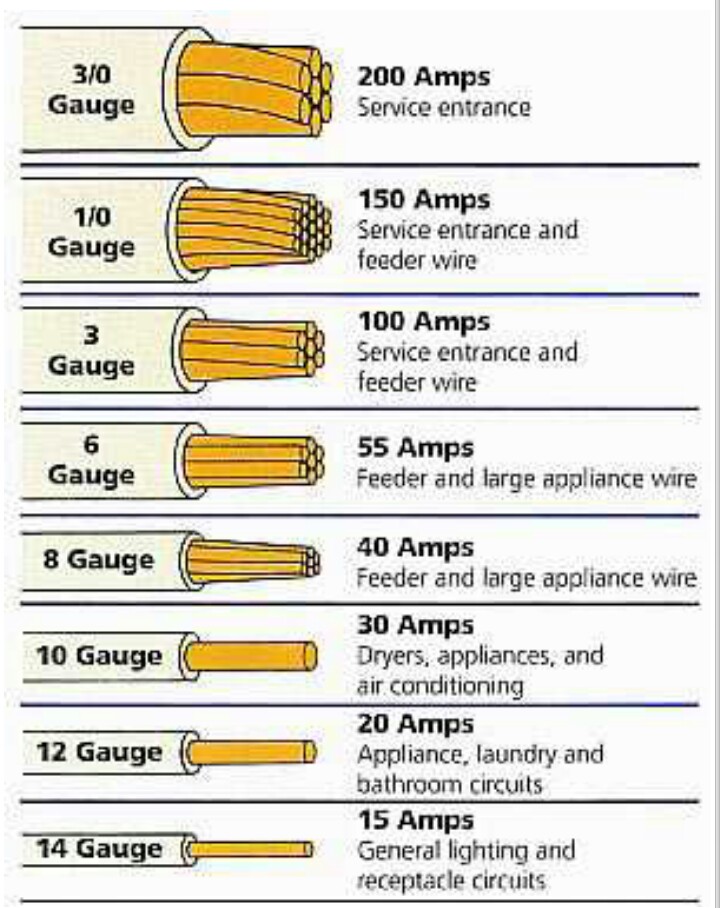

Now, wire size is measured in something called "gauge," and its a bit backwards. The smaller the number, the thicker the wire. So, a 6-gauge wire is thicker than a 12-gauge wire. Keep that in mind, it can be a bit confusing at first.

There are many type of wire that exist, such as copper, aluminum, and copper clad aluminum. Copper is the most common material for household wiring because its a great conductor of electricity. However, it's also more expensive than aluminum. Aluminum is lighter and cheaper, but it's not as conductive, so you'll need a thicker gauge for the same amperage. Copper-clad aluminum is a hybrid attempting to combine the best of both worlds, but it's not as widely used as either pure copper or pure aluminum.

Ampacity

2. Matching Wire Size to Amperage

Ampacity, the word itself sound intimidating, but it basically mean how much current a wire can safely handle, and it's affected by factors like the type of wire, its insulation, and where it's installed. For instance, wire running through insulation in your walls will have a lower ampacity than wire in open air because it can't dissipate heat as easily. Also, NEC (National Electrical Code) play important role in determine the ampacity of a wire.

So, what size wire for 60 amp circuit? For a 60 amp circuit with copper conductors, you'll generally want to use at least a 6 AWG (American Wire Gauge) copper wire. For aluminum conductors, you might need a 4 AWG wire to handle the same 60 amps. Always consult the National Electrical Code (NEC) or your local electrical codes for the most accurate and up-to-date information because codes can vary by location and application. The NEC is your bible when it comes to electrical safety, so don't skip it!

Remember that the environment where the wire is installed is important. If the wire is in a hot environment or bundled with other wires, its ampacity will be reduced. This is because heat buildup can cause the insulation to break down, which can lead to short circuits and fires. In these situations, you might need to upsize the wire to a larger gauge to ensure it can safely handle the current.

The length of the wire run also matters. For long runs, voltage drop can become a significant issue. Voltage drop is the decrease in voltage that occurs as electricity travels through a wire. If the voltage drops too low, your appliances might not function properly. To compensate for voltage drop, you might need to use a thicker wire to reduce resistance and maintain adequate voltage at the end of the run. There are online voltage drop calculators that can help you determine the appropriate wire size for long runs.

Electrical Wire Size For 60 Amp Service

Copper vs. Aluminum

3. Considering Conductor Material

Copper and aluminum are the two main contenders in the electrical wiring world. Copper is the champion for its superior conductivity, which means it allows electricity to flow through it more easily. This is why copper is often preferred for critical applications where efficiency and reliability are paramount. However, copper is also more expensive than aluminum, which can make aluminum an attractive option for budget-conscious projects.

Aluminum, on the other hand, is lighter and cheaper than copper, making it a popular choice for large-scale installations. However, it's not as conductive as copper, so you'll need a larger gauge aluminum wire to carry the same amount of current. Aluminum also expands and contracts more than copper with temperature changes, which can lead to loose connections over time. This is why aluminum connections need to be properly tightened and maintained to prevent problems.

The choice between copper and aluminum depends on your specific needs and budget. If you can afford it, copper is generally the better choice for its superior performance and reliability. However, if you're looking to save money and you're willing to take extra precautions with installation and maintenance, aluminum can be a viable option. Just make sure to follow all the relevant electrical codes and guidelines to ensure a safe and reliable installation.

One important consideration when using aluminum wire is that it requires special connectors that are designed for aluminum. These connectors are made from materials that are compatible with aluminum and help to prevent corrosion. Using the wrong type of connector can lead to loose connections and overheating, which can be a fire hazard. Always use connectors that are specifically labeled for use with aluminum wire.

Safety First! And Permits!

4. Protecting Yourself and Your Property

Alright, let's talk about the part that can make even the most seasoned DIYer sweat: safety. Electricity isn't something to mess around with. Before you even think about touching a wire, turn off the power at the breaker! Seriously, don't skip this step. It's the electrical equivalent of putting on a seatbelt. Also, invest in a good multimeter to check that the circuit is actually dead. Trust me, it's worth the small investment.

Another thing to keep in mind is that electrical work often requires a permit. I know, I know, permits can be a pain, but they're there for a reason. They ensure that your work is up to code and that your home is safe. Plus, if you ever decide to sell your home, having permitted electrical work can be a huge selling point. Check with your local building department to see if you need a permit for your project. Also, consider hiring a licensed electrician. They have the knowledge and experience to do the job safely and correctly. Think of it as an investment in your home and your peace of mind.

Wearing the right personal protective equipment is also essential. That means safety glasses, insulated gloves, and appropriate clothing. Avoid wearing jewelry or anything metal that could conduct electricity. Treat every wire as if it is live, even if you have turned off the breaker. Double-check and triple-check your work. Small mistakes can have big consequences when it comes to electricity.

Never work on electrical projects when you are tired or distracted. Electrical work requires focus and concentration. If you are feeling fatigued or stressed, take a break and come back to it later. It's better to take your time and do the job right than to rush and make a mistake. If you are not comfortable with any aspect of the electrical work, don't hesitate to call a professional. It's always better to be safe than sorry.

Voltage Drop

5. Accounting for Distance

Imagine you're trying to deliver water through a long hose. The farther you go, the less pressure you have at the end, right? That's voltage drop in a nutshell. It's the gradual decrease in voltage along the length of a wire. For short wire runs, it's usually not a big deal. But for longer runs, voltage drop can become a serious problem, causing appliances to malfunction or even fail.

So, how do you combat voltage drop? One way is to use a thicker wire. A thicker wire has less resistance, which means less voltage drop. Another way is to shorten the wire run, if possible. The shorter the distance, the less voltage drop. You can also use a higher voltage power source, but this is usually not practical for residential applications.

There are many online voltage drop calculators that can help you determine the appropriate wire size for your project. These calculators take into account the length of the wire run, the amperage of the circuit, and the voltage of the power source. Using a voltage drop calculator can help you ensure that your appliances are receiving the proper voltage and that your electrical system is operating safely and efficiently.

Ignoring voltage drop can lead to a variety of problems, including dim lights, slow-running motors, and overheating appliances. In extreme cases, voltage drop can even damage your appliances or cause a fire. That's why it's so important to calculate voltage drop and choose the right wire size for your project. Remember, it's always better to err on the side of caution when it comes to electricity.

Standard House Electrical Wire Size

FAQ

6. Frequently Asked Questions

Here are some frequently asked questions about "what size wire for 60 amp" service.

Q: Can I use a smaller gauge wire if the circuit breaker is rated for less than 60 amps?A: No, it's never a good idea to use a smaller gauge wire than what's recommended for the circuit. The circuit breaker is there to protect the wire, not the other way around. If you use a smaller gauge wire, it could overheat and cause a fire, even if the circuit breaker doesn't trip.

Q: What happens if I use a wire that's too small for a 60 amp circuit?A: Using a wire that's too small for a 60 amp circuit can be dangerous. The wire can overheat, melt the insulation, and potentially start a fire. It can also cause your appliances to malfunction and shorten their lifespan. Always use the correct wire size for the amperage of the circuit.

Q: Does the length of the wire affect the wire size I need?A: Yes, the length of the wire can affect the wire size you need, especially for longer runs. Voltage drop, which is the decrease in voltage along the length of a wire, can become a significant issue for long runs. To compensate for voltage drop, you might need to use a thicker wire to reduce resistance and maintain adequate voltage at the end of the run.