Neat Tips About How To Check If BOM Exists In SAP

Is There a Bill of Materials in My SAP System? Let's Find Out!

1. Why Bother Checking for a BOM Anyway?

Ever felt like you're wandering in the dark, trying to figure out what goes into making a specific product in SAP? That's where the Bill of Materials (BOM) comes in handy. Think of it as a recipe book for your products, detailing all the ingredients (materials, components) and steps (operations) needed to create the final dish. Knowing if a BOM exists, and what it contains, is crucial for planning, production, and cost management. It's like knowing you have all the right ingredients before you start baking, preventing that dreaded "oops, I'm missing the flour!" moment.

Without a properly defined BOM, you might end up ordering the wrong materials, scheduling production incorrectly, or even overspending because you didn't account for everything needed. It's a foundational piece of information that trickles down to almost every aspect of your manufacturing process. So, making sure that BOM is there, up-to-date and accurate is not just a "nice-to-have," it's a "must-have" for smooth operations and happy bean counters.

Essentially, checking for a BOM in SAP isn't just about ticking a box on a checklist. It's about ensuring your entire production process is built on solid ground. A reliable BOM means accurate material requirements planning (MRP), efficient production scheduling, and precise cost calculations. It's the key to unlocking streamlined operations and improved profitability, which is something every business strives for, right?

Imagine trying to assemble furniture without the instructions! Finding that BOM lets you get your bearings, know your components, and plan your course of action. Similarly, a BOM within SAP is your guide for the manufacturing process, it lays out the path from raw components to the finished product. Not having one can leave you scrambling and ultimately, costing time and money.

2. Different Roads to Discovering Your BOM

SAP offers several ways to check for the existence of a BOM. Let's explore some of the common methods. First off, Transaction Code CS03 is your best friend here. This transaction allows you to display a Bill of Materials. Simply enter the material code, plant, and BOM usage (usually '1' for production), and hit enter. If a BOM exists, you'll see its contents displayed. If not, SAP will politely inform you that no BOM was found. Don't worry, SAP always tries to be polite, even when delivering bad news.

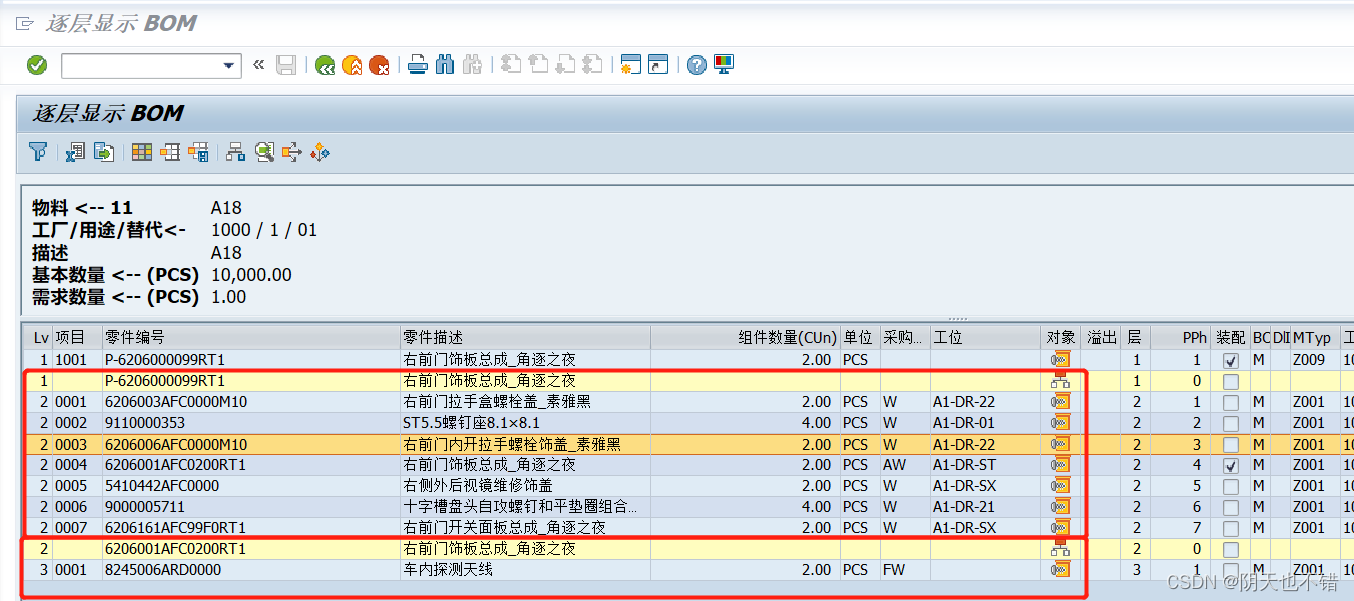

Another useful transaction is CS11. This is a bit more powerful; it's the 'Bill of Material Explosion'. It not only tells you if a BOM exists but also shows you the entire structure, including any sub-assemblies. Its like looking at a family tree, but for parts. It really visualizes the assembly structure. This can be extremely helpful for understanding complex products with multiple levels of components.

You could also check through material master data (Transaction Code MM03). Navigate to the 'MRP' views (specifically MRP 4), and look for the 'Selection Method' field. This field indicates how the system selects a BOM when multiple options exist. If this field is populated, it strongly suggests that at least one BOM is maintained for that material, but you will still want to verify by using one of the display transactions mentioned above. This method isn't a sure thing, but more like a breadcrumb.

Finally, if you have a feeling that a BOM should exist but can't find it, consider checking with your master data team or production planning department. Maybe the BOM exists but is restricted to a specific plant, or perhaps it's a variant BOM and you're not using the correct selection criteria. Teamwork makes the dream work! They might hold the secret code.

Using Transaction Code CS03 to Display a BOM

3. Step-by-Step Guide

Alright, let's dive into the specifics of using Transaction Code CS03. First, fire up your SAP system and enter 'CS03' in the transaction code field. Press Enter. You should now be looking at the 'Display Bill of Material: Initial Screen'. This is where the magic begins. Make sure you are logged into the appropriate client.

Next, you'll need to enter the key details. This includes the Material (the finished product you're interested in), Plant (the production location), and BOM Usage. For production BOMs, the BOM Usage is usually '1'. However, depending on your system configuration, it might be different, so double-check if you're unsure. These three fields are crucial because SAP uses them to identify the correct BOM.

Once you've entered the data, press Enter or click the green 'Continue' button. If a BOM exists for the specified material, plant, and usage, SAP will display the Bill of Material with all its components and quantities. You can then navigate through the BOM structure to see each level of the assembly. If, on the other hand, no BOM is found, SAP will display a message stating that no BOM exists for the selection criteria entered. Check your entries and retry. Don't panic; it happens to the best of us.

If no BOM is found, take a moment to double-check that you've entered the correct information. Pay close attention to the Material number and the Plant code, as these are the most common sources of errors. If you're still struggling, consider contacting your SAP support team for assistance. It's always better to ask for help than to waste time chasing ghosts. Also, verify you have authorization to view this data.

4. Interpreting the Results from CS03

So, you've run CS03 and the system has presented you with a Bill of Materials. Now what? The initial display usually shows you the header information, including the material number, plant, and valid-from date. Pay attention to the valid-from date, as this indicates when the BOM became active. Older BOMs might not be relevant if you're producing a current product version.

The main part of the screen displays the component list. Each row represents a component material used in the BOM. You'll see the material number, description, quantity required, and unit of measure. Make sure the quantities make sense. If you see a component listed with a ridiculously high quantity, it might indicate an error in the BOM. Question everything!

You can often drill down into each component to see more details, such as its material master data. This can be helpful for verifying the component's description, purchasing information, and other relevant data. This deeper dive could reveal issues that will cause production delays.

If you find discrepancies or errors, don't hesitate to report them to the responsible team. Maintaining accurate BOMs is a collaborative effort, and your input is valuable. After all, it's better to fix a problem early than to let it snowball into a major production issue. Nobody wants that headache!

Alternative Methods for BOM Verification

5. Leveraging the Material Master Record (MM03)

While CS03 is the go-to transaction, the Material Master record (accessed via MM03) offers a sneaky way to check for BOM clues. Navigate to the MRP views (MRP 1, MRP 2, MRP 4 are often key), and look for fields related to BOM selection or dependent requirements. A configured 'Selection Method' in MRP4 often hints at the presence of a BOM. It's not a guaranteed confirmation, but a strong indicator. Think of it as finding footprints near a campsite — something likely lives there, but you still need to find the tent. If you see something like a 'BOM application', then there is a BOM in effect.

Also, within the MRP views, keep an eye out for planning-related fields. If a material is planned using a specific planning strategy that relies on a BOM, it's highly probable that a BOM exists. For example, a strategy like "Make-to-Stock" might use a BOM to determine the component requirements for production. Basically, planning will need to know what parts to order.

Remember, using MM03 is more like detective work than a definitive answer. It provides clues that can lead you to the truth, but you'll still need to confirm your findings using CS03 or CS11. A quick note, MM02 is used to change the material master data, and MM01 is for creating a new material.

The material master data holds valuable information regarding the materials and related configurations within the SAP system. It is important to review all the information, because one missed configuration may cause errors in production. If you want to maintain accurate and efficient production processes, keeping the material master up to date is extremely important.

6. Exploring the Power of CS11

CS11, the BOM Explosion, is your secret weapon for uncovering complex BOM structures. Unlike CS03, which shows you a single level of the BOM, CS11 displays the entire multi-level structure. This is incredibly useful when dealing with products that have sub-assemblies and nested components. It paints the full picture. For example, a bike has a frame (sub-assembly) then wheels, seat etc. CS11 gives you a view of every sub-assembly.

Using CS11 is similar to CS03. You enter the material, plant, and BOM usage. However, CS11 offers additional selection criteria, such as the explosion date and quantity. These criteria allow you to simulate the BOM structure at a specific point in time or for a specific production quantity. This is particularly helpful when dealing with engineering changes or quantity-dependent components.

Once you run CS11, SAP will display the BOM structure in a tree-like format. You can expand or collapse each level to see the components and sub-assemblies. This visual representation makes it easy to understand the relationships between different parts of the product. You can also export the BOM structure to a spreadsheet for further analysis.

While CS11 is powerful, it can also be overwhelming, especially for complex products. Take your time to navigate the structure and focus on the areas that are most relevant to your needs. Using the filtering options can help you narrow down the results and focus on specific components or sub-assemblies. Also, remember that the authorization is key here, and you may not be able to see all the information if your user is not authorized.

SAP PP BOM Active Version & Inactive Check... Community