Nice Info About Is PWM The Same As DAC

Unraveling the Mystery

1. Decoding the Digital-to-Analog Puzzle

Have you ever found yourself scratching your head, pondering whether Pulse Width Modulation (PWM) is the same thing as a Digital-to-Analog Converter (DAC)? It's a common question, and honestly, the similarities can be a bit misleading at first glance. Both PWM and DAC are involved in creating analog signals, but they do it in fundamentally different ways. Think of it like this: they both want to get you to the same destination (an analog signal), but one takes the scenic route while the other prefers the highway. Let's dive a little deeper, shall we? We'll break down the differences, explain the processes in a way that hopefully makes sense, even if you're not an electrical engineer (like yours truly!).

The heart of the matter lies in their operation. A DAC, at its core, converts a digital number directly into an analog voltage or current. It's like having a translator that instantly understands and outputs the precise analog equivalent of each digital code. The digital signal is the input, and the resulting analog voltage is the output — simple, right? PWM, on the other hand, takes a different approach. It doesn't directly convert a digital number to an analog level. Instead, it manipulates the width of a pulse to represent an analog value. The wider the pulse, the higher the "average" voltage. It's a clever way to simulate an analog signal with a digital signal. So, while they both result in something that looks and acts like an analog signal, the underlying mechanics are quite distinct.

Another key distinction is accuracy. DACs are generally designed for higher precision. A good DAC will provide an accurate analog representation of the digital input. PWM, while versatile, often has inherent limitations in its accuracy. The "resolution" of a PWM signal is related to how many steps of width change you can realistically achieve. Think of it like drawing a circle. A DAC is like using a compass for smooth, accurate lines. A PWM signal is more like drawing the circle with tiny straight lines the more lines, the smoother the circle, but it will never be as smooth as the compass-drawn one. This becomes a more significant factor in applications requiring precise analog signals.

Finally, let's consider their applications. DACs are commonly found in audio equipment (converting digital audio files into sound), precision control systems, and measurement instruments. PWM, with its simplicity and efficiency, excels in motor control (speed and direction), LED dimming, and generating signals for power converters. The choice between PWM and DAC depends entirely on the specific requirements of the application the desired accuracy, the available processing power, and the cost constraints.

Deltasigma DACs And CODECs North Coast Synthesis Ltd.

PWM

2. How Does Pulse Width Modulation Work?

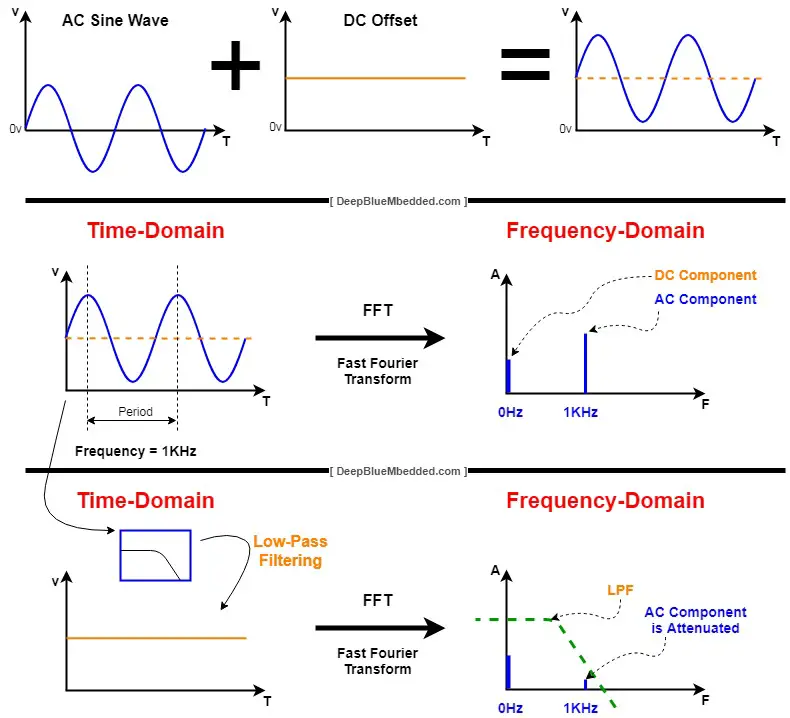

Lets get a bit more specific about how PWM actually works. Imagine you have a light switch that you can flip on and off very, very quickly. With PWM, you're essentially doing that rapidly switching a signal on and off. The trick is, you're varying the amount of time the signal is "on" compared to the amount of time it's "off." This ratio of on-time to off-time is called the "duty cycle." A 50% duty cycle means the signal is on for half the time and off for the other half. A 10% duty cycle means it's on for only 10% of the time and off for 90%. This manipulation of the duty cycle is how you create a simulated analog signal.

The human eye, for instance, can't perceive those super-fast on-off cycles. Instead, it averages them out. A 10% duty cycle on an LED will appear dimmer than a 50% duty cycle. Its like how old movies work theyre just a series of still frames flashed quickly enough that your brain sees motion. PWM is doing something similar, but with voltage or current instead of pictures. The beauty of PWM is its simplicity. It can be easily implemented using microcontrollers and other digital circuits. This makes it a cost-effective solution for many applications where high precision isn't paramount.

One important concept to understand is the "carrier frequency" of the PWM signal. This refers to how often the signal completes a full on-off cycle. A higher carrier frequency means the switching happens faster. While a faster switching speed is often better, there's a tradeoff. Higher frequencies can lead to increased switching losses in power electronics and may require more sophisticated filtering to smooth out the resulting analog signal. So, selecting the right carrier frequency is a crucial part of PWM design.

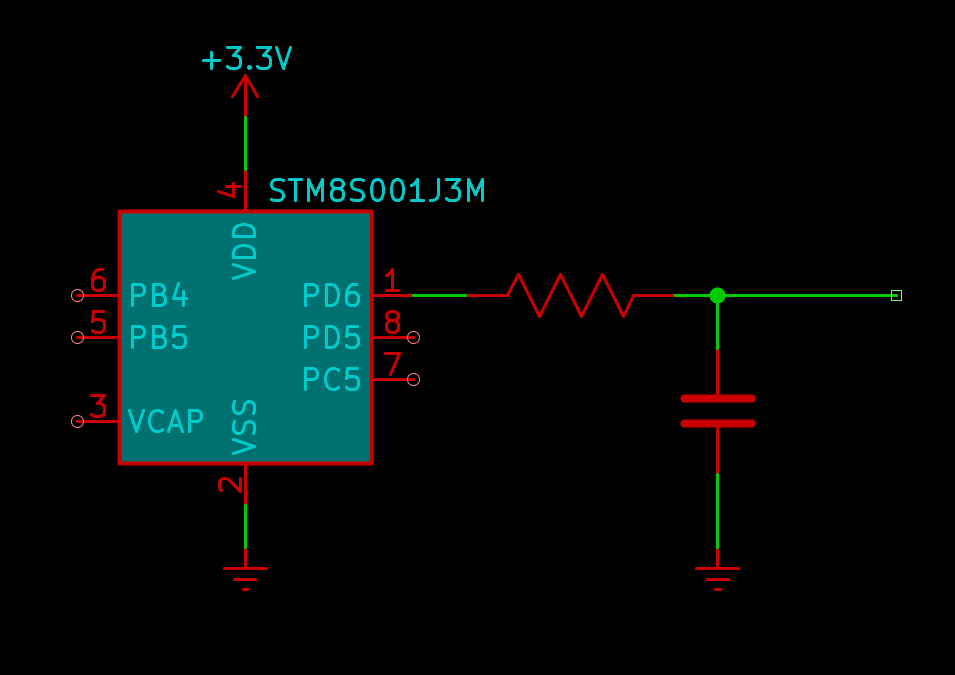

Furthermore, consider the effects of filters with PWM signals. Often, the raw PWM signal isn't smooth enough for the desired application. So, designers frequently use low-pass filters to smooth out the signal and remove the high-frequency switching components. This filtering process converts the pulse width modulated signal into a more stable analog voltage. Without this filter, the analog representation will be very noisy. The quality of the analog signal depends on the characteristics of the filter.

DAC

3. Understanding Digital-to-Analog Conversion

Now let's switch gears and explore the world of DACs. Unlike PWM, which simulates an analog signal, a DAC directly converts a digital number into a corresponding analog voltage or current. Think of it as having a lookup table where each digital input value has a unique analog output value. When you feed a digital code into a DAC, it instantly spits out the corresponding analog level. This direct conversion is what makes DACs so accurate and precise.

DACs are built using various architectures, each with its own strengths and weaknesses. Two common types are resistor ladder DACs and R-2R ladder DACs. Resistor ladder DACs use a network of resistors to create different voltage levels. R-2R ladder DACs, on the other hand, use only two resistor values (R and 2R) arranged in a specific pattern. This architecture is easier to manufacture with high precision and offers better performance. Sigma-delta DACs are another common type, which uses oversampling and noise shaping techniques to achieve high resolution and low noise. The choice of architecture depends on the application's requirements for accuracy, speed, and cost.

A crucial characteristic of a DAC is its resolution, usually specified in bits. A DAC with a higher bit resolution can produce more distinct analog output levels. For example, an 8-bit DAC can generate 256 (2^8) different voltage levels, while a 12-bit DAC can generate 4096 (2^12) levels. The higher the resolution, the finer the control over the analog output and the more accurate the representation of the digital input. This is particularly important in applications such as audio processing, where subtle variations in voltage can significantly affect the sound quality.

The speed of a DAC is also a significant factor, particularly in real-time applications. DACs have a parameter called the "settling time," which is the time it takes for the DAC output to reach and stabilize at its final value after a change in the digital input. A faster settling time allows the DAC to respond more quickly to changes in the input signal. In applications such as waveform generation and high-speed control systems, the settling time is crucial for maintaining accuracy and stability.

PWM To DAC Using STM32 As Blue Pill Sine Wave

Comparing the Two

4. Choosing the Right Tool for the Job

Okay, so weve looked at PWM and DAC individually. Now, lets put them head-to-head and figure out when you'd pick one over the other. The key considerations are typically accuracy, cost, and application. If you need high accuracy and a precise analog representation, a DAC is usually the best choice. Think of scientific instruments, high-end audio equipment, and precision control systems — these applications demand the superior accuracy that DACs provide. However, DACs are generally more expensive and complex than PWM circuits.

If cost is a major concern, and you don't need super-high precision, PWM is often the winner. Applications like motor control, LED dimming, and basic power control often benefit from the simplicity and low cost of PWM. It's a great way to get an "analog-ish" result with a digital signal. Think of it as using a wrench versus a laser cutter both can cut metal, but they have drastically different cost and precision levels.

Another factor is the application environment. PWM is often more robust and less susceptible to noise than DACs, especially in electrically noisy environments. This makes it a good choice for industrial applications and other situations where the signal might be exposed to interference. DACs, with their analog nature, are generally more sensitive to noise and require careful shielding and filtering to maintain their accuracy.

Ultimately, the choice boils down to a trade-off between cost, performance, and complexity. If you need the absolute best analog representation and are willing to pay for it, go with a DAC. If you're on a budget and just need a decent approximation, PWM is probably the way to go. And, of course, there are hybrid solutions where PWM and DAC are combined to achieve a balance between cost and performance. Sometimes, the best approach is to have your cake and eat it too!

Phasedarray PWM DAC EDN

Practical Examples

5. Seeing is Believing

To really nail down the differences, let's look at some real-world examples of where PWM and DACs shine. Imagine you're building a simple LED dimmer. A microcontroller can easily generate a PWM signal to control the LED's brightness. By changing the duty cycle of the PWM signal, you can smoothly adjust the LED from fully off to fully on. This is a common and inexpensive way to control light intensity. PWM is ideal because you dont need super-precise control, and its cost-effective.

Now, consider a high-end audio amplifier. Inside, you'll find DACs converting the digital audio data from your computer or streaming service into an analog signal that drives the speakers. Here, accuracy is critical. You want to hear every nuance and detail in the music, and that requires a DAC with high resolution and low distortion. A PWM signal wouldn't be able to reproduce the subtleties of the audio signal with sufficient fidelity. Imagine listening to your favorite song with missing notes — not ideal!

Another common application for PWM is motor control. By varying the duty cycle of a PWM signal applied to a motor, you can precisely control its speed and torque. This is used in everything from electric vehicles to robotics. The PWM signal essentially adjusts the average voltage applied to the motor, allowing for efficient and responsive control. In contrast, DACs are found in precision robotics and CNC machines, where highly accurate position and velocity control is essential.

Finally, think about the display on your smartphone or tablet. Many modern displays use DACs to generate the precise voltage levels needed to control the brightness and color of each pixel. This allows for a vibrant and accurate image. While PWM could theoretically be used to control display brightness, it would likely result in noticeable flickering or reduced color depth. The need for high accuracy and smooth gradients makes DACs the preferred choice in this application. So, next time youre watching a cat video on your phone, remember the DACs working hard behind the scenes!

PWM DAC_pwm模拟dacCSDN博客

FAQ

6. Clearing Up the Confusion

Still have questions? Thats perfectly normal! This stuff can be a little dense, so lets tackle some frequently asked questions to clear up any remaining confusion.

Q: Can PWM be used to generate audio?

A: Yes, technically it can. Early digital amplifiers used PWM. However, the quality won't be as good as a DAC. It would require significant filtering to remove the high-frequency switching noise and will likely result in distortion. For high-fidelity audio, DACs are the standard.

Q: Is a PWM signal always less accurate than a DAC signal?

A: Generally, yes. However, the accuracy of a PWM signal can be improved by increasing the switching frequency and using sophisticated filtering techniques. But, it's extremely difficult to match the accuracy of a good DAC.

Q: Can I use both PWM and DAC in the same circuit?

A: Absolutely! In some applications, PWM and DAC are used together. For example, a DAC might be used to provide a reference voltage for a PWM circuit, improving its accuracy. Or a PWM output might be "trimmed" using a DAC for calibration purposes. The possibilities are endless!